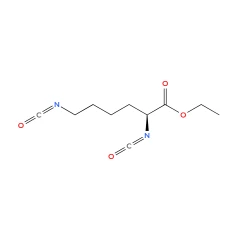

Name: L-Lysine Diisocyanate

Cas: 45172-15-4

Synonyms: LDI;lysine diisocyanate;Diisocyanate Ethyl Caproate;2,6-DiisocyanatoEthylCaproate;EthylEsterL-LysineDiisocyanate;L-Lysine Diisocyanate USP/EP/BP;L-Lysine diisocyanate ethyl ester;L-Lysineethylesterdiisocyanate,97%;(S)-Ethyl 2,6-diisocyanatohexanoate;Ethyl (S)-2,6-diisocyanatohexanoate

Purity: High purity

Prices are available upon request with our account manager for this product: [email protected]

**Pricing disclaimer

LDI (Cas 45175-15-4) is a versatile material that can be processed in biomaterials to result in non-toxic biodegradable polymers/ matrices. Our high purity material ensures a high quality end material.

Urethane elastomers have been used for decades in biomedical applications because of their wide range of physical properties.1–4 However, their use has been limited to nondegradable matrices synthesized with toluene diisocyanate (TDI) as the hard segment and a variety of polyesters or polyethers as the soft segment. Nevertheless, when these polymers slowly degrade, their degradation product, 2,4-diaminotoluene, tends to be toxic in vivo. Attempts to replace TDI with aliphatic diisocyanates such as 4,4-methylenedicyclohexyl diisocyanate and hexamethylene diisocyanate have met with similar concerns of toxicity, because the diamines liberated during their degradation are still relatively toxic. Yet, except for their toxicity, urethanes possess many attributes that are ideal for biomedical applications. For example, urethane chemistry provides a wide range of synthetic options that can be varied through changing the hard segment (diisocyanate), the polyol, the chain extenders, and/or the ratios in which they are reacted. These modifications in the chemistry can be utilized to affect the mechanical and biological properties of the matrices. Attempts to replace the hard segment of urethanes to obtain nontoxic polymers have met with limited success. This was due either to the contaminants present in the hard segment preparations or to the inherent problems associated with the soft segments.

A study from Zhang J.-Y et al (2019) reported the ability to make non-toxic biodegradable polymers. They showed to make a LDI–glucose polymer that possesses many attributes which are potentially useful in tissue-engineering and other biomedical applications. The authors state that LDI polymerized with glucose yields a matrix that can be foamed in aqueous solutions for use as scaffolds for cell growth. LDI–glucose polymer foam is biodegradable and its degradation products are nontoxic and do not alter the pH of PBS. LDI–glucose foam exhibits physical properties that are suitable for cell growth in vitro. The LDI–glucose polymer is nonimmunogenic and induces minimal foreign body reactions in the form of capsule formation in vivo.